Every plumber should have one. You can’t beat the petrol saw for power and by far the best thing is being able to use the saw inside with no fumes. I’ve been sick many times due to the effects of carbon monoxide but no longer. The amazing added benefits are the cleanliness of cutting with the reduced slurry. The exhaust vacuum is great too for all types of cleanup including drain cleaning.

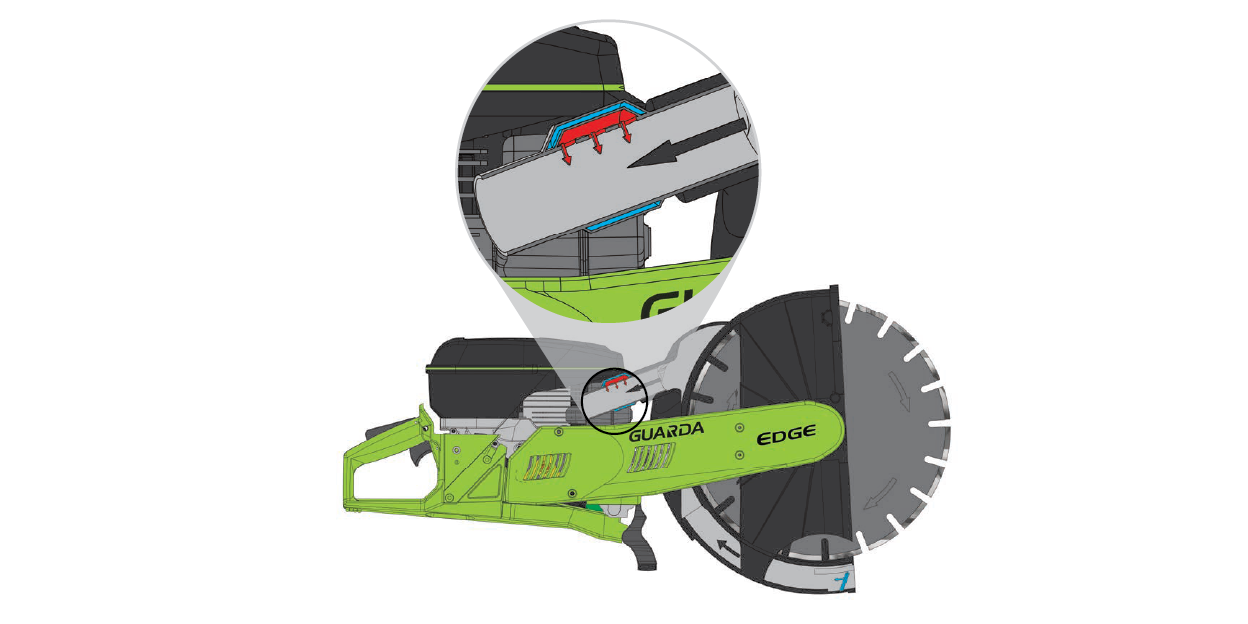

The Guarda Edge Power Cutter wins the 2019 Most Innovative Product Award at the World of Concrete Trade Show.