When it comes to cutting tools, safety is a big deal, especially with materials that can kick up harmful dust like silica. The Edge Power Cutter stands out in this regard, designed not just for performance but also to meet safety standards that protect workers on the job.

Key Takeaways

- The Edge Power Cutter is built to meet silica safety standards, ensuring worker safety.

- Features like dust suppression technology and closed blade housing minimise harmful dust exposure.

- Safety tests show the Edge Power Cutter outperforms many competitors in dust control.

- Proper user guidelines are essential for safe operation and maintenance of the cutter.

- Industry feedback highlights the effectiveness of the Edge Power Cutter in real-world scenarios.

Understanding Silica Safety Standards

Overview of Silica Risks

Okay, so let’s talk about silica. It’s basically sand, right? But when you cut things like concrete or stone, you create really fine dust. This dust can contain crystalline silica, and that’s the stuff that can cause problems. Breathing it in over time can lead to silicosis, a lung disease. It’s not something you want to mess with. So, what are the risks? Well, long-term exposure can cause serious and irreversible lung damage. It’s a big deal, and that’s why there are standards in place to protect workers.

Importance of Compliance

Why bother with all the safety stuff? Well, first and foremost, it’s about protecting your health and the health of your workers. But there’s also the legal side of things. WorkSafe and other regulatory bodies have rules about silica exposure, and if you don’t follow them, you could face some hefty fines. Plus, being compliant shows that you care about your team, and that can improve morale and productivity. Compliance isn’t just a box to tick; it’s about creating a safe and responsible work environment. So, does the Edge Cutter comply with silica laws? We’ll get to that, but understanding why compliance matters is the first step.

Key Regulatory Bodies

In Australia, WorkSafe is the main body you need to know about when it comes to workplace health and safety, including how to meet WorkSafe dust regulations. They set the standards and enforce them. There are also other organisations that provide guidance and resources, like Safe Work Australia. It’s worth checking their websites to stay up-to-date on the latest regulations and best practises. Knowing who sets the rules helps you make sure you’re doing things right. These bodies are there to help keep workplaces safe, so it’s a good idea to know what they expect. The goal is to ensure everyone goes home healthy at the end of the day. The table below shows the exposure limits:

| Regulatory Body |

Exposure Limit (mg/m3) |

| WorkSafe |

0.1 |

| Safe Work Australia |

0.1 |

It’s important to remember that these limits are guidelines, and the best approach is always to minimise exposure as much as possible. Using tools with features that reduce silica exposure is a great way to do this.

Features of the Edge Power Cutter

Dust Suppression Technology

The Edge Power Cutter comes with some pretty neat dust suppression tech. Basically, it’s designed to keep the amount of airborne silica dust to a minimum. How does it do this? Well, it uses integrated water jets that spray water directly onto the blade during cutting. This traps the dust particles before they can become airborne and cause a health hazard. It’s a simple idea, but it makes a big difference on the worksite. This helps keep everyone breathing easier and reduces the risk of long-term health problems.

Closed Blade Housing Benefits

One of the standout features of the Edge Power Cutter is its closed blade housing. This design offers several advantages:

- Enhanced Safety: The enclosed housing minimises the risk of accidental contact with the blade, protecting the operator and those nearby.

- Improved Dust Control: It helps contain dust and debris generated during cutting, further reducing airborne particles.

- Reduced Noise: The housing dampens the noise produced by the blade, creating a quieter work environment.

The closed blade housing is a game-changer. It not only makes the tool safer to use but also contributes to a cleaner and more comfortable work environment. It’s a win-win for everyone involved.

Optional Suppression Kits

To further enhance dust control, the Edge Power Cutter offers optional suppression kits. These kits can be added to the standard setup to provide even greater protection against silica dust exposure. These kits usually include:

- High-Volume Water Tank: A larger water tank allows for extended use without the need for frequent refills.

- Adjustable Spray Nozzles: These nozzles allow you to fine-tune the water spray pattern to match the specific cutting task.

- Vacuum Attachment: A vacuum attachment can be connected to a dust collection system for maximum dust removal.

These optional kits provide an extra layer of protection, making the Edge Power Cutter a versatile tool for any job site where silica dust is a concern.

Performance Testing and Safety Data

Results from Safety Tests

Okay, so when we talk about the Edge Power Cutter, it’s not just about how well it cuts. It’s also about how safe it is to use, right? We’ve put this thing through a bunch of tests to make sure it meets all the safety standards. These tests look at things like how much dust it kicks up, how well the blade guard works, and whether it’s likely to cause any injuries. The results have been pretty good, showing that it keeps dust levels low and protects the user from the blade.

- Airborne dust particle counts during operation.

- Blade guard effectiveness under stress.

- Noise level measurements during cutting.

Comparative Analysis with Competitors

How does the Edge Power Cutter stack up against other power cutters on the market? That’s a fair question. We’ve done a comparative analysis, looking at things like dust suppression, vibration, and overall safety features. Vibration is a big one, because too much vibration can lead to fatigue and increase the risk of accidents. We also looked at how easy it is to use and maintain, because let’s be honest, no one wants a tool that’s a pain to deal with.

| Feature |

Edge Power Cutter |

Competitor A |

Competitor B |

| Dust Suppression |

Excellent |

Good |

Average |

| Vibration |

Low |

Moderate |

High |

| Ease of Use |

Very Easy |

Easy |

Difficult |

Real-World Usage Scenarios

All the lab tests in the world don’t mean much if a tool doesn’t perform well in the real world. So, we’ve also been testing the Edge Power Cutter in actual worksites, with real tradies using it for their day-to-day jobs. This gives us a good idea of how it handles different materials, different conditions, and different users. We’ve been collecting feedback from the users, and so far, it’s been mostly positive. They like how easy it is to use, how little dust it kicks up, and how safe it feels.

One thing we’ve learned from these real-world tests is that proper training is key. Even the safest tool can be dangerous if it’s not used correctly. So, make sure everyone who uses the Edge Power Cutter gets the proper training and knows how to use it safely.

User Guidelines for Safe Operation

Operating any power tool safely is super important, and the Edge Power Cutter is no exception. It’s not just about avoiding accidents; it’s about making sure everyone on site goes home safe at the end of the day. These guidelines will help you use the cutter properly and keep everyone around you safe.

Pre-Operation Safety Checks

Before you even think about turning the Edge Power Cutter on, give it a good once-over. I mean, really look at it. Is the blade in good nick? Are all the guards in place and working properly? Check the power cord for any damage – frays or cuts. If you spot anything dodgy, don’t use it. Get it fixed first. Also, make sure you’ve got the right personal protective equipment (PPE). We’re talking safety glasses, a dust mask (especially when cutting materials that create dust), and hearing protection.

Here’s a quick checklist:

- Inspect the blade for damage or wear.

- Verify all safety guards are correctly installed and functional.

- Check the power cord for any signs of damage.

- Ensure you have the correct PPE: safety glasses, dust mask, and hearing protection.

Best Practises During Use

When you’re actually using the Edge Power Cutter, there are a few things to keep in mind. Always keep a firm grip on the tool and maintain a stable stance. Don’t overreach or try to cut at awkward angles. Let the tool do the work; don’t force it. If you’re cutting something that creates a lot of dust, use the dust suppression system if your cutter has one, or consider using an optional suppression kit. And never, ever remove any of the safety guards. They’re there for a reason.

Post-Operation Maintenance

Once you’re done cutting, don’t just chuck the tool in a corner. Give it a bit of TLC. Unplug it, clean off any dust or debris, and inspect it for any damage. If you notice anything that needs fixing, get it sorted out before you use it again. Store the cutter in a dry, safe place where it won’t get damaged or be a hazard to anyone. Regular maintenance will keep your cutter running smoothly and safely for years to come.

Proper maintenance is key to extending the life of your Edge Power Cutter and ensuring it operates safely. A little bit of care goes a long way.

Integrating Edge Power Cutter into Worksites

So, you’ve got an Edge Power Cutter. Great! But just having the tool isn’t enough. You need to think about how it fits into your worksite and how to use it safely and effectively. It’s about more than just cutting; it’s about creating a safe environment for everyone.

Training for Operators

Proper training is absolutely vital. Don’t just hand someone the Edge Power Cutter and say, “Have at it!” That’s a recipe for disaster. Make sure everyone who uses the tool understands:

- How the tool works.

- The risks involved, especially with silica dust.

- How to use the dust suppression features.

- What to do in case of an emergency.

Regular refresher courses are also a good idea, especially if there are updates to safety procedures or the tool itself. It’s an investment that pays off in the long run by preventing accidents and keeping your team safe. Are you using compliant concrete cutting equipment?

Safety Equipment Recommendations

Beyond the Edge Power Cutter itself, you’ll need other safety gear. Think of it as a complete package:

- Respirators: A must for protecting against silica dust. Make sure they’re properly fitted and maintained.

- Eye protection: Safety glasses or goggles to prevent debris from getting into the eyes.

- Hearing protection: Cutting concrete can be noisy, so earplugs or earmuffs are essential.

- Protective clothing: Long sleeves, pants, and gloves to protect the skin.

Don’t skimp on safety equipment. It’s not just about ticking boxes; it’s about protecting your team’s health and well-being. If you are not using the correct safety equipment, you may be in breach of OSHA concrete saw regulations.

Creating a Safe Work Environment

It’s not just about the individual operator; it’s about the whole worksite. Here are some things to consider:

- Ventilation: Ensure there’s adequate ventilation to minimise dust exposure.

- Water supply: If using wet cutting methods, make sure there’s a reliable water source.

- Clearance: Keep the work area clear of obstructions and unnecessary personnel.

- Signage: Use clear signage to warn of potential hazards.

By taking these steps, you can create a worksite where the Edge Power Cutter can be used safely and effectively. Remember, safety is everyone’s responsibility.

Feedback from Industry Professionals

It’s one thing to say our Edge Power Cutter meets silica safety standards, but it’s another to hear it from the people who use it every day. We’ve gathered feedback from industry professionals to give you a real-world perspective on its performance and safety.

Testimonials from Users

We’ve been collecting feedback from tradies and construction workers who’ve put the Edge Power Cutter to the test. What are they saying? Well, a lot of them are impressed with how much it cuts down on dust.

- “I used to cough all day after cutting concrete, but not anymore!”

- “The dust suppression is a game-changer. I can actually see what I’m doing now.”

- “It’s lighter than my old cutter, and the safety features give me peace of mind.”

One thing that keeps coming up is how easy it is to use. Even guys who aren’t tech-savvy can pick it up quickly. They also appreciate the reduced cleanup time, which means they can get more done in a day. It’s not just about safety; it’s about efficiency too.

Case Studies of Successful Implementation

Let’s look at some specific examples. We worked with a demolition company in Melbourne that was struggling to meet the new silica regulations. They were facing fines and delays, and morale was low. After switching to the Edge Power Cutter, they saw a significant improvement. Dust levels dropped dramatically, and they passed their safety inspections with flying colours.

Another case involved a tiling company in Sydney. They were concerned about the long-term health of their workers. They implemented a training programme around the Edge Power Cutter and provided the recommended safety equipment. The result? Fewer sick days and a happier, more productive workforce. These case studies show that it’s not just about buying the right tool; it’s about integrating it into a comprehensive safety plan.

Expert Opinions on Safety Features

We also consulted with safety experts to get their take on the Edge Power Cutter. They highlighted several key features that contribute to its safety performance. The closed blade housing is a big one, as it contains dust and debris. The dust suppression technology is also crucial, as it reduces the amount of airborne silica. And the optional suppression kits provide an extra layer of protection for high-risk environments.

Experts agree that the Edge Power Cutter represents a significant step forward in cutting technology. They emphasise the importance of proper training and maintenance to ensure its continued safe operation. It’s not a magic bullet, but it’s a valuable tool in the fight against silica exposure.

Here’s a quick summary of expert opinions:

- Closed blade housing: Minimises dust escape.

- Dust suppression: Reduces airborne particles.

- Ergonomic design: Improves user comfort and control.

Future Innovations in Cutting Technology

What’s next for cutting tech? It’s a question we’re always asking ourselves, especially when it comes to safety. Things are changing fast, and it’s exciting to see where we’re headed. Let’s have a look at some of the innovations on the horizon.

Emerging Trends in Safety Standards

Safety standards are always getting tighter, and that’s a good thing. We’re seeing a big push for real-time monitoring of dust levels and exposure. This means sensors built directly into cutting tools that can alert operators to unsafe conditions immediately. Also, there’s more focus on ergonomics, making tools easier and less tiring to use, which reduces the risk of accidents. It’s not just about meeting the minimum requirements anymore; it’s about creating a genuinely safe work environment.

Advancements in Dust Control

Dust control is a huge area of innovation. We’re moving beyond basic water suppression to more advanced systems that capture dust at the source with greater efficiency. Think about things like:

- Improved filtration systems that can handle even the finest silica particles.

- Robotic cutting systems that can operate in enclosed environments, minimising dust exposure.

- New materials for cutting blades that produce less dust in the first place.

The goal is to eliminate dust exposure as much as possible, not just reduce it. This requires a combination of better technology and smarter work practises.

The Role of Technology in Enhancing Safety

Technology is playing a massive role in making cutting jobs safer. We’re seeing more and more tools with built-in sensors, data logging, and even AI-powered safety features. Imagine a cutting tool that can automatically adjust its speed and power based on the material it’s cutting, minimising the risk of kickback or blade failure. Or systems that use virtual reality to train operators in safe cutting techniques. The possibilities are endless, and the future of cutting is looking a lot safer thanks to these advancements.

As we look ahead, cutting technology is set to evolve in exciting ways. Innovations like smart cutting tools and advanced dust suppression systems will not only improve efficiency but also enhance safety for workers. If you want to stay updated on the latest advancements in cutting technology, visit our website for more information and resources!

Wrapping Up: Safety First with the Edge Power Cutter

In summary, the Edge Power Cutter stands out when it comes to safety, especially regarding silica dust. With features like effective dust suppression and a closed blade housing, it really ticks the boxes for meeting safety standards. Plus, if you look at the product specs, you’ll see how it goes above and beyond to keep users safe. Whether you’re a pro or just tackling a DIY project, this tool helps you work smarter and safer. So, if you’re in the market for a reliable cutter that prioritises safety, the Edge Power Cutter is definitely worth considering.

Frequently Asked Questions

What are silica safety standards?

Silica safety standards are rules designed to protect workers from the harmful effects of silica dust, which can cause serious health issues like lung disease.

How does the Edge Power Cutter help with silica safety?

The Edge Power Cutter has special features that reduce dust, like dust suppression technology and a closed blade housing, making it safer to use.

What is dust suppression technology?

Dust suppression technology uses water or other methods to keep dust from flying around while cutting, helping to keep the air clean.

Are there any tests that show the Edge Power Cutter is safe?

Yes, the Edge Power Cutter has gone through safety tests that show it meets or exceeds silica safety standards, ensuring it is safe for workers.

What should I do before using the Edge Power Cutter?

Before using the cutter, always check it for any damage, make sure all safety features are working, and wear the right protective gear.

Can I get training on how to use the Edge Power Cutter safely?

Yes, it’s important to have training for operators to ensure they know how to use the cutter safely and effectively.

If you’re diving into concrete cutting, Guarda’s Concrete Cutting System is definitely the best practice option. This kit packs everything you need to get the job done right, from the world’s best dust suppression technology to an efficient vacuum system to high-quality blades. It’s designed to make your cutting tasks easier and more efficient, whether you’re a pro or just starting out. Let’s break down what’s inside this kit and how each part plays a role in your concrete cutting projects.

Key Takeaways

- Guarda’s concrete cutting system includes essential tools like cutting blades and a powerful, dust suppressing saw.

- Each component is designed to work together for maximum efficiency.

- Safety gear is a must-have and included in the kit to protect you during use.

- Regular maintenance of your kit can significantly extend its lifespan.

- Visual aids like diagrams and videos can help you understand how to use the kit effectively.

Understanding The Concrete Cutting Kit

Overview of the Concrete Cutting System

So, you’re thinking about getting into concrete cutting? Or maybe you’re just tired of hiring someone every time you need to make a clean cut. Either way, understanding what a concrete cutting kit actually is, is the first step. A full cutting system isn’t just one tool; it’s a collection of tools and equipment designed to tackle concrete cutting jobs safely and efficiently. It’s about having the right gear on hand to get the job done right, from start to finish. It’s a bit like having a well-stocked toolbox for a specific trade – everything you need, all in one place.

Importance of Each Component

Each piece in a concrete cutting kit plays a vital role. It’s not just about having a saw that can efficiently cut concrete. Think about it: you need the right blade for the type of concrete you’re cutting, a way to control the dust, and, other safety gear to protect yourself. The saw provides the power, the blades do the cutting, the dust suppression keeps you safe, and additional safety equipment provides additional safety benefits. Skimping on any one component can lead to poor results and health hazards.. It’s a system where each part supports the others.

How the Kit Enhances Efficiency

Ever tried cutting concrete with the wrong tools? It’s slow, messy, and frustrating. A full cutting system takes the guesswork out of the equation. When choosing a complete cutting solution, you’re not just buying tools; you’re investing in efficiency. You’ll spend less time setting up, less time cleaning up, and less time struggling with inadequate equipment. Plus, having everything you need in one kit means you’re less likely to have to stop mid-job to run to the hardware store. It’s about streamlining the whole process, so you can focus on getting the job done quickly and professionally. When considering what’s included in a concrete cutter kit, think about the time saved, not just the initial cost.

Key Components of Guarda's Concrete Cutting System

Powerful Concrete Saw

The saw itself is the engine of the whole operation. It needs enough grunt to power through dense materials without bogging down. Power isn’t everything, though. You also want a saw that’s well-balanced and easy to handle, reducing fatigue during long jobs. Guarda’s saws are designed with ergonomics in mind, so you can maintain control and precision, even when cutting at awkward angles. Plus, features like vibration dampening can make a big difference in comfort and safety. It’s like driving a car – you want something with enough power to get the job done, but also something that’s comfortable and easy to handle.

Effective Dust Suppression System

Concrete dust is a serious health hazard. That’s why an overview of Guarda’s integrated dust suppression system is so important. It’s not just about keeping the job site clean; it’s about protecting your lungs. Guarda’s dust suppression systems use water to trap dust particles at the source, preventing them from becoming airborne and a vacuum to remove the resultant slurry. This not only improves visibility but also reduces the risk of respiratory problems. The system is designed to be efficient, using just enough water to control the dust and an efficient vacuum system to contain the slurry before it escapes into the environment. It’s a bit like having a built-in vacuum cleaner for your saw, keeping the air and surroundings clean and safe.

Here are some key benefits of a good dust suppression system:

- Reduces airborne dust particles

- Prevents slurry from escaping into the environment

- Removes exhaust fumes and harmful carbon monoxide

- Protects the operator’s respiratory health

A good dust suppression system is one of the most important components needed for safe concrete cutting. It’s an investment in your health and the health of those around you.

High-Quality Cutting Blades

When you’re tackling concrete, the blade is where the rubber meets the road, or rather, where the diamond meets the aggregate. It’s not just about spinning fast; it’s about the quality of the diamonds embedded in the blade and how well they’re bonded. A cheap blade might save you a few bucks upfront, but you’ll be replacing it much sooner, and the cuts won’t be as clean. Guarda uses blades designed for specific types of concrete and aggregate, ensuring optimal performance and longevity. Think of it like using the right tool for the job – a screwdriver won’t work as well as a wrench on a nut, and a general-purpose blade won’t cut as efficiently as one designed for reinforced concrete.

How Each Component Works Together

Regular Inspection of Components

Keeping your concrete cutting kit in tip-top shape starts with regular checks. I usually give everything a good once-over before and after each use. Look for anything obvious – cracks, loose bolts, worn cables, that sort of thing. Catching small issues early can save you from bigger headaches (and expenses) down the road.

Here’s a quick checklist I use:

- Check cutting blades for damage or wear.

- Inspect the power cord for cuts or fraying.

- Make sure all guards and safety features are working properly.

- Tighten any loose nuts or bolts

- Check and clean the air filter

- Ensure hoses are not blocked.

Cleaning and Storage Guidelines

Dust and debris are the enemy of any power tool. After each job, I make sure to clean all the components of my concrete cutting kit thoroughly. Water and a brush and a bit of elbow grease usually do the trick. Proper cleaning not only keeps your tools looking good but also prevents them from performing poorly or breaking down prematurely.

I keep my kit in a sturdy toolbox to protect it from the elements and accidental damage. Make sure the blades are covered or stored separately to prevent injury.

Extending the Lifespan of Your Kit

Want to get the most out of your concrete cutting kit? Here are a few extra tips I’ve picked up over the years:

- Use the right blade for the job. Don’t try to cut reinforced concrete with a blade designed for softer materials.

- Apply coolant or water as directed by the manufacturer. This helps to keep the blade cool and reduces dust.

- Don’t force the saw. Let the blade do the work at its own pace.

- Follow the manufacturer’s maintenance schedule for things like oil changes and filter replacements.

By following these simple maintenance tips, you can keep your concrete cutting kit in top condition and extend its lifespan. This not only saves you money in the long run but also ensures that your tools are always ready when you need them. A well-maintained kit is a safe and efficient kit.

Support Material for Understanding the System

Images and descriptions of the System and how to use it

Sometimes you just need to see the real deal in action. That’s why we include detailed descriptions and plenty of images in the operating instructions and other collateral material describing and showing the concrete cutting kit being used in different scenarios along with correct maintenance techniques. It’s like having a silent instructor guiding you through each step.

Video Tutorials for Assembly and Use

Alright, let’s be honest, sometimes reading instructions just don’t cut it (pun intended!). That’s where video tutorials come to the rescue. We’ve created a series of videos that walk you through everything from assembling the kit for the first time to performing different types of concrete cuts. You’ll see real people demonstrating the techniques, explaining the safety precautions, and troubleshooting common issues. It’s like having a personal trainer for your concrete cutting kit. Plus, you can pause, rewind, and re-watch as many times as you need until you feel confident.

Video tutorials are a great way to learn because you can see exactly what to do, rather than just reading about it. It’s especially helpful for visual learners, and it can save you a lot of time and frustration in the long run.

Here’s a quick rundown of what you might find in the video tutorials:

- Unboxing and initial setup

- Step-by-step assembly instructions

- Demonstrations of different cutting techniques

- Safety tips and best practices

- Troubleshooting common issues

Where to Purchase the Concrete Cutting Kit

Official Product Page

The first place you should check for the Guarda concrete cutting kit is the official product page on Guarda’s website. This is the best place to get the most accurate and up to date product information, including the latest specifications, warranty details, and any available promotions.

Retailers and Online Options

You can find the Guarda concrete cutting system via the distributor network outlined on the website, When buying from a third-party retailer, make sure to check their return policy and warranty information.

Comparing Prices and Offers

Before making a purchase, it’s a good idea to compare prices from different sources. Prices can vary depending on current promotions, and shipping costs. Look out for bundled deals that might include extra blades or safety gear at a discounted price. Also, consider signing up for newsletters or following distributors on social media to stay informed about upcoming sales and special offers. Don’t just focus on the lowest price; factor in the distributors reputation, warranty, and customer service.

When comparing prices, remember to factor in shipping costs, taxes, and any potential import duties if you’re buying from overseas.

Here’s a quick checklist to help you compare offers:

- Check the total price, including shipping and taxes.

- Review the distributors return policy.

- Look for bundled deals or promotions that add value.

Wrapping Up Your Concrete Cutting Journey

In conclusion, the Guarda Full Concrete Cutter System has the world’s best silica dust suppression for anyone looking to tackle concrete cutting tasks. Each component, from the blade to the vacuum, is designed to work in harmony, making your job safer, easier and more efficient. Whether you’re a DIY enthusiast or a seasoned pro, having the right tools can make all the difference. If you want to learn more about each part or see the system in action, check out the product page linked above. Happy cutting!

Frequently Asked Questions

What is included in Guarda’s Concrete Cutting System?

The system has everything you need, including high-quality cutting blades, a powerful concrete saw, with a built in dust suppression system and a vacuum, hoses and fittings.

How do I use the concrete cutting saw?

To use the saw, make sure to wear your safety gear and follow the set up and operating instructions carefully.

Why is dust suppression important when cutting concrete?

Dust suppression helps keep the air clean and protects your lungs from harmful silica dust particles that can be released during cutting.

How can I maintain my concrete cutting kit?

Regularly check the components for damage, clean the blades and saw after use, and store everything in a dry place.

Where can I buy Guarda’s Concrete Cutting System?

You can find information on the system on the Guarda website product page, and purchase it via various distributors as featured on the Guarda website.

What safety gear should I wear when using the kit?

Always wear safety glasses, gloves, hearing protection and consider respiratory protection to keep yourself safe while cutting.

In the construction and manufacturing industries, safety is paramount. One often overlooked piece of equipment that can significantly enhance jobsite safety is the vacuum generator. These devices play a vital role in maintaining a clean and safe working environment by effectively controlling dust and debris generated during various tasks. This blog post will explore how vacuum generators contribute to improved safety on jobsites, their benefits, and how they can be integrated with existing tools.

Key Takeaways

- Vacuum generators are essential for effective dust control during cutting and drilling tasks.

- Improved air quality leads to a healthier work environment and reduces health risks for workers.

- Both portable and built-in vacuum systems have their advantages, depending on jobsite needs.

- Integrating vacuum generators with tools can streamline operations and enhance safety features.

- Compliance with safety regulations is crucial, and vacuum generators help meet these standards.

Understanding The Role Of Vacuum Generators

Function In Active Cutting

Okay, so what’s the deal with vacuum generators when you’re actually cutting stuff? Basically, they’re all about sucking up the dust and debris right at the source. Think about it: when you’re using a saw or grinder, there’s a heap of stuff flying around. A vacuum generator, connected to your tool, creates suction that pulls all that mess away before it has a chance to spread. This means you can actually see what you’re doing, which makes for cleaner, more accurate cuts. It also stops the dust from getting into the air, which is a win for everyone’s lungs.

Importance In Dust Collection

Dust collection is a big deal on any jobsite, and vacuum generators play a critical role. Why? Because they’re super effective at removing fine particles that can hang around in the air for ages. These particles, especially things like silica dust from concrete, are really bad news for your health. A good vacuum generator will have a high-efficiency philtre (like a HEPA philtre) that traps even the tiniest bits. This keeps the air cleaner, reduces the risk of respiratory problems, and helps you meet safety regulations. It’s not just about being tidy; it’s about looking after yourself and your workmates.

Enhancing Tool Efficiency

Believe it or not, vacuum generators can actually make your tools work better. How? By removing dust and debris, they stop your tools from getting clogged up. Think about a sander, for example. If the sandpaper gets covered in dust, it won’t cut as well, and you’ll have to replace it more often. A vacuum generator keeps the sandpaper clean, so it lasts longer and works more efficiently. This means you get the job done faster, with less wear and tear on your equipment. Plus, a cleaner tool is generally a safer tool, as it’s less likely to overheat or malfunction.

Benefits Of Using Vacuum Generators On Jobsites

Improved Air Quality

On any vacuum generator jobsite, one of the most noticeable improvements is the air quality. Dust and debris, especially when you’re doing things like concrete cutting, can really make the air thick and hard to breathe. A vacuum generator sucks up these particles right at the source, preventing them from becoming airborne in the first place. This means everyone on site is breathing cleaner air, which is a big win for long-term health.

Reduced Health Risks

Breathing in construction dust isn’t just unpleasant; it can lead to serious health problems down the line. Things like silicosis, lung cancer, and other respiratory illnesses are real risks for workers who are constantly exposed. By using a vacuum generator for dust extraction, you’re actively reducing these risks. It’s about more than just meeting regulations; it’s about looking after the well-being of your crew.

Enhanced Worker Productivity

It might seem counterintuitive, but cleaner air can actually boost productivity. When workers aren’t constantly coughing, struggling to breathe, or taking breaks to get away from the dust, they can focus better on the task at hand. Plus, a cleaner jobsite is generally a safer jobsite, which means fewer accidents and less downtime. Investing in safe concrete cutting tools and dust control is an investment in your team’s efficiency and overall output. It also helps in reducing exposure with dust containment.

Using a vacuum generator is a proactive step towards creating a healthier and more efficient work environment. It demonstrates a commitment to worker safety and can lead to significant long-term benefits for both employees and the company.

Here’s a simple breakdown of how a vacuum generator can impact productivity:

- Fewer respiratory issues = less sick leave.

- Cleaner environment = improved focus.

- Safer conditions = reduced accidents.

- Compliance with regulations = avoiding fines and delays.

Ultimately, the benefits of using a vacuum generator extend beyond just compliance; they contribute to a more positive and productive work culture. It’s about how vacuum helps meet safety standards and creates a better environment for everyone involved. By design, Guarda’s Vacuum Generator is a compact, lightweight and petrol-powered which makes it an agile but reliable model perfect for removing fumes, dust and slurry.

Comparing Portable And Built-In Vacuum Systems

Choosing the right vacuum system for your jobsite can feel like a big decision. You’ve basically got two main options: portable units and built-in systems. Both have their pros and cons, and what works best really depends on the specific needs of your worksite, the type of work you’re doing, and, of course, your budget. Understanding the differences between extractors and suppression systems is key to making the right choice.

Flexibility Of Portable Units

Portable vacuum units are all about convenience. Need to move around the site a lot? These are your go-to. They’re easy to transport, set up, and store, making them ideal for smaller jobs or sites where you don’t have a fixed workspace. Plus, you can easily move them between different tools as needed. This flexibility is a major advantage for many tradies.

Here’s a quick rundown of the benefits:

- Easy to move between locations.

- Simple setup and storage.

- Good for smaller jobs and varied tasks.

Advantages Of Built-In Systems

Built-in vacuum systems, on the other hand, are designed for larger, more permanent setups. Think workshops or factories where you have dedicated workstations. These systems offer powerful and consistent suction across multiple points, making them great for heavy-duty tasks and continuous use. They often have larger collection capacities, meaning less frequent emptying.

Key advantages include:

- High suction power for demanding tasks.

- Large collection capacity, reducing downtime.

- Suitable for fixed workstations and continuous use.

Cost Considerations

Cost is always a factor, right? Portable units generally have a lower upfront cost, making them accessible for smaller businesses or individual tradies. However, built-in systems, while more expensive to install, can be more cost-effective in the long run for larger operations due to their efficiency and reduced maintenance needs. You need to factor in not just the initial purchase price, but also ongoing costs like philtre replacements and electricity usage.

When weighing up the costs, think about the long-term benefits. A cheaper portable unit might seem appealing initially, but if it’s constantly breaking down or not providing adequate dust control, it could end up costing you more in the long run through repairs, downtime, and potential health issues.

Integrating Vacuum Generators With Existing Equipment

Compatibility With Tools

So, you’re thinking about adding a vacuum generator to your setup? First thing’s first: will it actually work with the tools you’ve already got? Most vacuum generators are designed to be pretty universal, but it’s always worth double-checking. Look at the hose fittings – are they the same size? Does your tool need a specific airflow rate that the generator can handle? It’s better to measure twice and cut once, as they say.

- Check the tool’s manual for recommended vacuum requirements.

- Consider using adaptors if the fittings don’t match up.

- Test the setup before starting a big job to avoid surprises.

Streamlining Operations

Okay, so the vacuum generator fits – now, how can it actually make your work easier? Think about where you’re placing the generator. Is it out of the way, or are you constantly tripping over it? Can you easily switch it between different tools? A well-integrated system should save you time and effort, not add to it.

A good setup means less mucking around and more actual work getting done. It’s about making the whole process smoother, from start to finish.

Maximising Safety Features

This is where vacuum generators really shine. By sucking up dust and debris right at the source, you’re not just keeping the jobsite cleaner – you’re also protecting yourself and your workers. Make sure the generator is properly sealed to the tool, so you’re not losing suction. And don’t forget to regularly empty the collection bag or container. A full container means reduced suction and, well, what’s the point then?

- Ensure all connections are airtight to prevent dust leaks.

- Regularly inspect hoses for damage or blockages.

- Use the correct philtre for the type of dust you’re dealing with.

Regulatory Compliance And Safety Standards

Meeting Health Regulations

When it comes to jobsite safety, understanding and adhering to health regulations is really important. These regulations, often set by governing bodies, are there to protect workers from harmful substances and conditions. For example, in Australia, Safe Work Australia plays a big role in setting standards. It’s not just about avoiding fines; it’s about creating a work environment where everyone can go home healthy at the end of the day. Vacuum generators can be a key part of meeting these regulations, especially when it comes to controlling dust and other airborne particles.

Importance Of Dust Control

Dust control is a big deal on many jobsites. Construction, demolition, and even woodworking can generate a lot of dust, which can cause some serious health problems. Think about silicosis from silica dust, or respiratory issues from other types of particulate matter. Effective dust control measures are not just a ‘nice to have’; they’re a legal requirement in many cases. Vacuum generators, when used with the right tools, can significantly reduce the amount of dust in the air, making the jobsite safer for everyone. It’s about preventing long-term health issues and ensuring a better quality of life for workers.

Best Practises For Jobsite Safety

Okay, so how do you actually make a jobsite safer using vacuum generators? Here are a few best practises:

- Regularly inspect and maintain your vacuum systems. A broken vacuum is about as useful as a chocolate teapot.

- Use the right philtres for the type of dust you’re dealing with. Not all philtres are created equal.

- Make sure workers are properly trained on how to use the equipment and understand the risks involved.

Implementing these practises isn’t just about ticking boxes; it’s about creating a culture of safety. When workers see that their health and well-being are a priority, they’re more likely to take safety seriously themselves.

Ultimately, it’s about making sure everyone goes home safe and sound.

Case Studies: Successful Implementations

Real-World Applications

Let’s look at how vacuum generators are making a difference on Aussie jobsites. We’re not just talking theory here; these are real examples of companies that have adopted the technology and seen tangible improvements. Think of a construction firm in Sydney dealing with silica dust while cutting concrete. Or a woodworking shop in Melbourne trying to keep the air clean during sanding operations. These are the kinds of scenarios where vacuum generators shine.

- Concrete Cutting: A Sydney-based construction company, faced with increasing regulations around silica dust, integrated vacuum generators into their concrete cutting saws. This drastically reduced airborne dust, creating a safer environment for workers and minimising the risk of respiratory illnesses.

- Woodworking: A small woodworking business in Melbourne installed a central vacuum system powered by a vacuum generator. This system connected to their sanders and saws, capturing dust at the source and improving air quality in the workshop.

- Demolition: A demolition crew in Brisbane used vacuum-assisted tools to remove asbestos-containing materials. The vacuum system captured asbestos fibres, preventing them from becoming airborne and protecting workers and the surrounding community.

Feedback From Workers

What do the workers actually think about using vacuum generators? It’s one thing to read about the benefits, but the real test is how it impacts their day-to-day work. Generally, the feedback is positive. Workers report:

- Reduced Dust Exposure: This is the most common benefit mentioned. Workers feel they are breathing cleaner air and are less worried about long-term health effects.

- Improved Visibility: With less dust in the air, workers can see what they are doing more clearly, leading to better accuracy and fewer mistakes.

- Increased Comfort: Some workers have noted that the reduced dust and debris make for a more comfortable and pleasant working environment.

“Before we got the vacuum system, the dust was terrible. You’d be coughing all day, and everything was covered in a layer of grime. Now, it’s so much cleaner. I actually feel like I can breathe at the end of the day.”

Impact On Jobsite Safety

Ultimately, the goal is to make jobsites safer. So, how do vacuum generators contribute to this? Here’s a breakdown:

- Reduced Respiratory Hazards: By capturing dust and debris at the source, vacuum generators minimise the risk of workers inhaling harmful particles. This is particularly important for materials like silica, asbestos, and lead.

- Improved Visibility: As mentioned earlier, clearer visibility reduces the risk of accidents and injuries. Workers can see potential hazards more easily and avoid slips, trips, and falls.

- Compliance With Regulations: Vacuum generators help companies meet increasingly strict health and safety regulations. This reduces the risk of fines and legal action.

Vacuum generators are not a silver bullet, but they are a valuable tool in creating safer and healthier jobsites. They represent a proactive approach to worker safety and demonstrate a commitment to protecting the well-being of employees. By investing in this technology, companies can create a more productive and sustainable work environment.

Future Trends In Vacuum Technology

Vacuum technology is always changing, and it’s pretty interesting to see where things are headed. It’s not just about making things suck up dust better; there’s a lot more going on under the hood. Let’s have a look at some of the things we can expect to see in the near future.

Innovations In Design

We’re seeing some cool stuff in vacuum generator design. Think smaller, more powerful units that can be easily integrated into existing tools. Manufacturers are focusing on making them lighter and more durable, so they can handle the rough and tumble of a jobsite.

- Modular designs are becoming more common, allowing for easier maintenance and repairs.

- New materials are being used to reduce noise and vibration.

- Smart features, like sensors that detect blockages or philtre issues, are starting to appear.

Sustainability Considerations

Sustainability is a big deal these days, and vacuum technology is no exception. People are looking for ways to reduce their environmental footprint, and that includes the tools they use on the jobsite. Energy efficiency is key.

- Vacuum generators are being designed to use less power.

- Philtres are being made from recycled materials and designed to last longer.

- Manufacturers are exploring ways to recycle or repurpose old units.

The Role Of Automation

Automation is creeping into all sorts of industries, and vacuum technology is no different. Imagine vacuum systems that can automatically adjust their suction power based on the type of material being cut or ground. That’s the kind of thing we’re talking about.

Automation can also help to improve safety by reducing the need for workers to be in close proximity to dust-generating activities. This is especially important in industries where exposure to hazardous materials is a concern.

- Robotic systems with integrated vacuum technology are becoming more common.

- AI is being used to optimise vacuum performance and predict maintenance needs.

- Remote monitoring and control systems are making it easier to manage vacuum systems from a distance.

As we look ahead, vacuum technology is set to evolve in exciting ways. Innovations will likely focus on making systems more efficient and user-friendly, while also reducing their environmental impact. This means we can expect smarter devices that not only perform better but also help us save energy. If you want to stay updated on the latest advancements in vacuum technology, visit our website for more information and resources!

Wrapping Up: The Importance of Vacuum Generators for Safety

In summary, vacuum generators play a key role in keeping job sites safe. They effectively collect harmful silica dust while tools are in use, which helps protect workers’ health. Whether you opt for portable units or built-in systems, the technology from Guarda stands out for its efficiency and integration. By investing in these solutions, you not only comply with safety regulations but also create a healthier work environment. It’s a win-win for everyone involved.

Frequently Asked Questions

What does a vacuum generator do during cutting?

A vacuum generator helps to suck away dust and debris while cutting, making the air cleaner and safer.

How does it help with dust collection?

It collects harmful silica dust that can be released when using tools, keeping the job site safer.

What are the differences between portable and built-in vacuum systems?

Portable units can be moved around easily, while built-in systems are fixed but may offer better integration with tools.

Can I use vacuum generators with my existing tools?

Yes, many vacuum generators can work with different tools, making them a great addition to your equipment.

Why is dust control important on job sites?

Dust control is vital because it reduces health risks for workers and helps meet safety regulations.

What are some future trends in vacuum technology?

Future trends include new designs, eco-friendly options, and more automation to improve efficiency.

Wall chasing is a technique used in construction to create channels in walls for various services like electrical wiring and plumbing. It involves cutting into the wall material to make space for these installations. This method is quite common, but it comes with its own set of challenges and considerations. In this article, we’ll explore what wall chasing is, its benefits, the tools required, and the associated risks, as well as some innovative solutions in this area.

Key Takeaways

- Wall chasing is essential for installing electrical and plumbing systems within walls.

- Proper tools and techniques are crucial for effective wall chasing and minimising damage.

- Safety measures are necessary to manage dust and vibrations during the wall chasing process.

- Innovative tools, like those from Guarda, help reduce dust, slurry and fumes and improve efficiency in wall chasing.

Understanding Wall Chasing

Definition of Wall Chasing

Wall chasing is a construction technique used to create narrow channels, or ‘chases’, in walls. These chases are primarily made to embed electrical wiring, plumbing pipes, or other utilities neatly within the wall structure. Think of it as creating a hidden pathway for essential services, keeping them out of sight and protected. It’s a far tidier solution than surface-mounted conduits, offering a clean, streamlined finish to interior spaces. The difference between wall chasing and slot cutting is subtle; wall chasing typically refers to creating longer, continuous channels, while slot cutting might involve shorter, more isolated cuts.

Common Applications in Construction

So, what is wall chasing used for? Well, you’ll find it used in a variety of construction scenarios:

- Electrical Wiring: Hiding cables for power outlets, light switches, and other electrical fixtures.

- Plumbing: Concealing water pipes for sinks, showers, and other plumbing installations.

- Data and Communication Cables: Embedding network cables, telephone wires, and other communication lines.

- HVAC Systems: Creating space for small ductwork or refrigerant lines.

Wall chasing is common in both residential and commercial buildings, especially where aesthetics are a priority or where brick or concrete walls are used. It’s also frequently used in renovations to update older buildings with modern wiring and plumbing without disrupting the existing structure too much.

Benefits of Wall Chasing

There are several good reasons why builders and renovators opt for wall chasing:

- Aesthetics: Provides a clean, uncluttered look by concealing unsightly wires and pipes.

- Protection: Protects utilities from damage, wear and tear, and accidental interference.

- Space Saving: Maximises usable space by eliminating the need for bulky surface-mounted conduits.

- Increased Safety: Reduces the risk of tripping hazards and electrical shocks by keeping wires safely tucked away.

Wall chasing, while effective, requires careful planning and execution. It’s important to consider the structural integrity of the wall and the placement of utilities to avoid any potential problems down the line. Using the right tools and techniques is also crucial for achieving a clean, professional finish.

Ultimately, chase cutting offers a blend of practicality and visual appeal, making it a popular choice in modern construction.

Tools and Techniques for Wall Chasing

Definition of Wall Chasing

Wall chasing, at its core, is the process of cutting narrow channels into walls. These channels are primarily used to conceal electrical wiring, plumbing pipes, or other utilities. It’s a common practice in construction and renovation projects, allowing for a neat and aesthetically pleasing finish by hiding unsightly cables and pipes within the wall structure. The depth and width of the chase depend on the size of the conduits or pipes being installed.

Common Applications in Construction

Wall chasing isn’t just for hiding wires; it has a range of applications. You’ll find it used extensively in:

- Electrical installations: Creating pathways for wiring for power outlets, lighting, and switches.

- Plumbing: Concealing water pipes, especially in bathrooms and kitchens.

- Data and communication cables: Hiding network cables and telephone wires.

- HVAC systems: Integrating refrigerant lines for air conditioning units.

Basically, any situation where you want to run services within a wall without exposing them is a candidate for wall chasing.

Benefits of Wall Chasing

Why bother with wall chasing? Well, the benefits are pretty clear:

- Aesthetics: Creates a clean, uncluttered look by concealing services.

- Safety: Protects wires and pipes from damage, reducing the risk of electrical shock or leaks.

- Space saving: Maximises usable space by embedding services within the wall.

- Increased property value: A well-finished, modern look can increase the appeal and value of a property.

Essential Tools for Wall Chasing

Okay, so you’re ready to start chasing some walls. You’ll need the right tools for the job. Here’s a rundown of the essentials:

- Wall Chasing Saw: This is the primary tool, essentially a specialised concrete chasing saw designed to cut one or two parallel lines simultaneously. Guarda saws have the advantage of more effective dust suppression and are safer overall compared with conventional wall chasing machines or angle grinders.

- Dust Extraction System: A vacuum cleaner is a must. Guarda’s unique solution pairs a wet vacuum with a wall chasing saw to remove dust, slurry and exhaust fumes.

- Chisels and Hammers: For removing the material between the cuts made by the wall chaser or angle grinder.

- Safety Gear: Safety glasses, respirator, ear protection, and gloves are non-negotiable.

Techniques for Effective Wall Chasing

Effective wall chasing isn’t just about having the right tools; it’s about using them correctly. Here are some techniques to keep in mind:

- Planning: Mark out the chase clearly on the wall before you start cutting. Consider the location of existing services to avoid damage.

- Cutting: Follow the wall marks and let the saw do the work. This reduces strain on the tool and minimises chipping.

- Dust Control: Use a dust extraction system at all times.

- Material Removal: Use a chisel and hammer to carefully remove the material between the cuts during dual blade cutting. Avoid excessive force to prevent damaging the surrounding wall.

Safety Measures During Wall Chasing

Wall chasing can be dangerous if you don’t take the proper precautions. Safety should always be your top priority. Here are some key safety measures:

- Wear appropriate PPE: Always wear safety glasses, a respirator, ear protection, and gloves.

- Isolate power: Turn off the power to any electrical circuits in the area you’re working in.

- Check for hidden services: Use a stud finder or other detection device to locate any pipes or wires hidden within the wall.

- Take breaks: Wall chasing can be physically demanding, so take regular breaks to avoid fatigue.

Wall chasing is a skilled task that requires careful planning, the right tools, and a commitment to safety. By following these guidelines, you can achieve professional results while minimising the risks involved.

Risks Associated with Wall Chasing

Wall chasing, while useful, isn’t without its downsides. It’s important to be aware of these risks and take steps to minimise them. Ignoring these potential problems can lead to costly repairs, safety hazards, and even structural damage. Let’s have a look at some of the main things to watch out for.

Dust and Debris Management

Wall chasing without dust extraction creates a lot of airborne dust and debris. This is a major health and safety concern. Breathing in dust, especially silica dust from concrete or brick, can cause serious lung problems like silicosis.

To manage dust and debris:

- Use dust extraction tools connected to your wall chaser.

- Wear a properly fitted P2 or P3 dust mask.

- Consider sealing off the work area with plastic sheeting to contain the dust if in a public area.

Potential Structural Impacts

Incorrect wall chasing can weaken the structure of a building. Cutting too deep, removing too much material, or chasing in the wrong places (like load-bearing walls) can compromise the integrity of the wall. This can lead to cracks, instability, and in extreme cases, even collapse.

Always check structural plans before starting any wall chasing work. If you’re not sure, consult a structural engineer to assess the potential impact of your planned chases.

Vibration Concerns

Wall chasing generates a lot of vibration. This vibration can result in hand-arm vibration syndrome (HAVS) in workers who operate the wall chaser for extended periods.

To minimise vibration risks:

- Use anti-vibration gloves.

- Take regular breaks to reduce exposure time.

- Ensure the wall chaser is properly maintained and in good working order.

Innovations in Wall Chasing Technology

Wall chasing has come a long way, hasn’t it? What used to be a pretty manual and dusty job is now being transformed by some seriously cool tech. Let’s have a look at some of the latest advancements.

Guarda’s Edge Tools for Wall Applications

Guarda are making some waves in the wall chasing world. They’re known for their robust design and focus on user safety. I’ve seen a few tradies using their gear on site, and the feedback is very positive. They seem to be hitting that sweet spot between performance and reliability.

Guarda tools often feature enhanced vibration dampening and ergonomic designs, which can make a big difference when you’re spending hours chasing walls. Plus, their dust extraction capabilities are definitely the best by far.

Future Trends in Wall Chasing

So, what’s next for wall chasing? I reckon we’ll see even more automation and precision in the coming years. Think robotic wall chasers, laser-guided systems, and AI-powered tools that can detect hidden obstacles. It sounds like something out of a sci-fi movie, but it’s probably not that far off!

- Robotic wall chasing systems.

- AI-powered obstacle detection.

- Lighter, more durable materials for tools.

- Increased focus on noise reduction.

Best Practices for Wall Chasing

Wall chasing, when done right, can save time and money, and it looks neater too. But it’s not something you want to rush into without a plan. Let’s look at some best practices to make sure you’re doing it properly and safely.

Planning and Preparation Steps

Before you even think about picking up a wall chaser, a bit of planning goes a long way. First, figure out exactly where your cables or pipes need to go. Mark it all out clearly on the wall. Double-check for any hidden pipes or wires using a detector – you really don’t want to hit those!

Here’s a quick checklist:

- Map it out: Draw the planned routes on the wall.

- Check for hazards: Use a detector to find hidden services.

- Gear up: Get your safety gear ready (more on that later).

Choosing the Right Materials

Using the right materials makes a big difference to the final result. For filling the chases after you’ve run your cables, consider using a quality filler that’s easy to sand and paint. Some fillers are specifically designed for electrical work, so they’re a good bet. Also, make sure your cable clips or ties are suitable for the job and the type of wall you’re working with.

Environmental Considerations in Wall Chasing

Wall chasing, like any construction activity, has an environmental footprint. It’s not just about the immediate job; it’s about thinking long-term and minimising any negative impact on our surroundings. From dust control to responsible waste disposal, there are plenty of ways to make wall chasing more sustainable. Let’s look at how we can do our bit.

Minimising Environmental Impact

Wall chasing can create a fair bit of mess, but there are ways to keep the environmental impact down. One of the biggest issues is dust. Using tools with effective dust extraction systems is a must. These systems capture the dust at the source, preventing it from becoming airborne and polluting the surrounding environment. Also, think about the noise. Using quieter tools and working at reasonable hours can help reduce noise pollution, especially in residential areas.

Sustainable Practices in Wall Chasing

Going green in wall chasing isn’t just a trend; it’s a responsibility. Here are a few sustainable practices to consider:

- Use eco-friendly materials: When backfilling or patching up chases, opt for materials with recycled content or those that are sustainably sourced.

- Water Management: If water is used for dust suppression, ensure its managed responsibly to avoid runoff and water wastage.

- Proper Equipment Maintenance: Regularly maintain your wall chasing tools. Well-maintained equipment operates more efficiently, reducing energy consumption and emissions.

Thinking about the environment doesn’t have to be hard. Small changes in how we approach wall chasing can make a big difference. It’s about being mindful of the resources we use and the waste we create.

Recycling Materials from Wall Chasing

What happens to all the rubble and debris after wall chasing? Don’t just dump it! Recycling is a great way to reduce landfill waste. Sort the materials – concrete, brick, and plasterboard can often be recycled. Check with your local recycling centre or waste management company to see what they accept. Even small amounts of metal from old wiring can be recycled. By taking the time to recycle, you’re helping to conserve resources and reduce the environmental impact of your project.

Comparing Wall Chasing Methods

Conventional vs Guarda Method

Wall chasing has come a long way, mate! Up until recently most wall chasing was done without dust suppression or with ineffective dust suppression. Now, with Guarda’s innovative dust suppression technology, wall chasing is safer and faster. Let’s have a look.

- Relies on conventional wet or dry-vacuum dust suppression.

- Slower and more labour-intensive.

- Generated a lot of dust and debris.

- Uses water and vacuum combined to effectively manage silica dust, slurry and fumes

- Leaves a cleaner worksite

- More likely to be compliant with dust and other regulations.

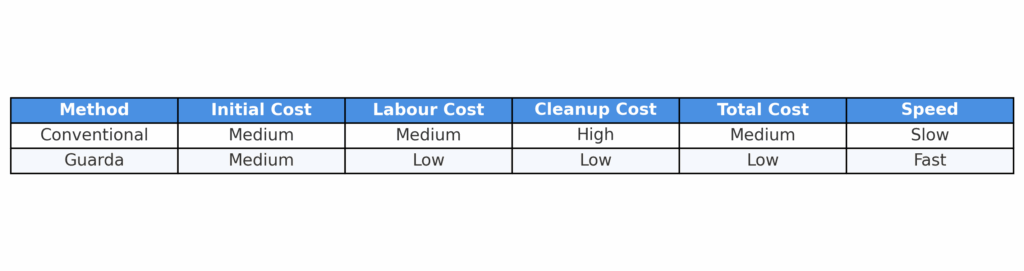

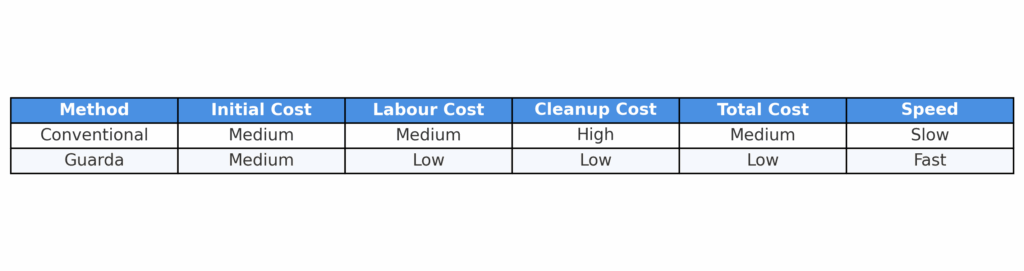

Cost Analysis of Different Methods

Okay, let’s talk dollars and cents. The initial cost of modern wall chasing equipment can be a bit of a shock. But when you factor in the time saved and the reduced cleanup, it might actually work out cheaper in the long run. Here’s a rough breakdown:

*Labour cost will vary depending on the hourly rate of the tradesperson and the complexity of the job. It’s worth getting a few quotes to compare the costs of different methods for your specific project.

Efficiency of Various Approaches

Efficiency isn’t just about speed; it’s about getting the job done right with minimal fuss. Modern wall chasers, such as Guarda’s are far more efficient in terms of time, labour, and cleanup. They also offer greater precision, which can reduce the risk of damaging the surrounding wall.

- Precision: Modern tools offer better control and accuracy.

- Dust Control: Integrated dust extraction minimises mess and health risks.

- Time Savings: Faster, more powerful tools significantly reduce the time required to complete the job.

Wrapping Up: Understanding Wall Chasing

In summary, wall chasing is a handy technique in construction for running electrical and plumbing services through walls. While it can make installations cleaner and more efficient, it’s not without its challenges. The dust and vibrations can be a nuisance, and there’s always a risk to the structure itself if not done carefully. So, if you’re considering wall chasing, make sure you’re equipped with the right tools or book the right service, especially those with the most effective dust suppression. Guarda’s system is a great choice for this kind of work. Overall, understanding the ins and outs of wall chasing can help you make informed decisions and achieve better results in your projects.

Frequently Asked Questions

What is wall chasing?

Wall chasing is a method used in construction to create grooves in walls. This allows for the installation of electrical wires or plumbing pipes without them being visible on the surface.

Why is wall chasing important?

Wall chasing is important because it helps keep walls looking neat and tidy. It hides wires and pipes, making a building safer and more attractive.

What tools are needed for wall chasing?

To chase walls, you typically need a wall chaser tool, a diamond blade, and safety gear like safety glasses and respirators to protect against dust.

What are the risks of wall chasing?

Some risks include creating a lot of dust, which can be harmful to breathe in, and possibly damaging the structure of the wall if not done with best practice dust suppression.

How can I manage dust when wall chasing?

Using tools, like Guarda’s with built-in dust control features can help manage dust. Also, wearing respirators and working in well-ventilated areas can reduce dust exposure.

What are some best practices for wall chasing?

Always plan your work, choose the right materials, use the best dust suppression technology available and finish the wall properly after chasing to ensure a good result.

Dust suppression on construction sites is more important than many people realise. Silica dust can pose serious health risks. In this article, we’ll explore why controlling dust during masonry cutting is essential, the regulations surrounding it, and how Guarda Systems is making a difference with their dust control solution. We’ll also look at the costs involved and best practise for keeping construction sites safe and compliant.

Key Takeaways

- Airborne dust can cause significant health risks, particularly from crystalline silica exposure.

- Compliance with silica dust regulations is crucial to avoid exposing workers and hefty fines.

- Investing in effective dust suppression can lead to long-term cost savings.

- Guarda Systems provides innovative solutions for effective dust control on construction sites.

- Regular training and monitoring are essential for maintaining dust control compliance.

Understanding The Risks Of Airborne Dust

Construction sites, while hubs of progress, unfortunately also generate a lot of dust. It’s easy to dismiss it as a minor nuisance, but airborne dust poses significant risks that need addressing. Let’s look at why dust suppression is so important.

Health Hazards Associated With Silica Dust

One of the biggest concerns is silica dust. This is created when materials like concrete, stone, and sand are cut, ground, or drilled. When inhaled, these tiny particles can cause serious and irreversible lung damage. Prolonged exposure can lead to silicosis, a debilitating lung disease, as well as an increased risk of lung cancer and other respiratory problems. It’s not just a long-term risk either; even short-term exposure can result in irreversible lung damage.

Environmental Concerns Related To Dust

It’s not just people who are affected; airborne dust also has environmental consequences. Dust clouds can travel long distances, settling on surrounding vegetation and water sources. This can disrupt local ecosystems, affecting plant growth and water quality. Dust deposition can also contaminate soil, altering its composition and potentially harming wildlife. Furthermore, the sheer volume of dust generated by construction sites contributes to air pollution, impacting air quality in surrounding areas. It’s a problem that extends beyond the site itself.

Regulatory Compliance And Its Importance

Navigating the world of construction isn’t just about hard hats and heavy machinery; it’s also about understanding and adhering to a complex web of regulations. Compliance with workplace safety standards is not merely a suggestion; it’s a legal obligation designed to protect workers, the environment, and the community. Ignoring these rules can lead to hefty fines, project delays, and, most importantly, put lives at risk. Let’s break down why regulatory compliance is so important.

Overview Of WorkSafe And OSHA Regulations

In Australia, WorkSafe is the primary body responsible for overseeing workplace health and safety. They set the standards, conduct inspections, and enforce regulations to ensure businesses provide a safe working environment. Similarly, in other countries, organisations like OSHA (Occupational Safety and Health Administration) in the United States play a comparable role. These bodies have specific guidelines regarding dust control, particularly concerning silica compliance, given the severe health risks associated with inhaling silica dust. Understanding the specific requirements of WorkSafe in your state or territory is the first step towards ensuring a safe and compliant construction site. These regulations often cover:

- Permissible exposure limits (PELs) for hazardous substances like silica.

- Requirements for air monitoring and personal protective equipment (PPE).

- Mandatory training programmes for workers on dust control measures.

Consequences Of Non-Compliance

Failing to meet regulatory requirements can have serious repercussions. The consequences extend beyond just financial penalties. Here’s what you might face:

- Fines: WorkSafe and similar bodies can issue substantial fines for breaches of safety regulations. These fines can quickly add up, especially for repeat offences.

- Project Delays: Non-compliance can lead to work stoppages while issues are addressed, causing significant delays and cost overruns.

- Legal Action: In severe cases, companies and individuals can face legal action, including prosecution for negligence.

- Reputational Damage: A poor safety record can damage your company’s reputation, making it harder to win contracts and attract skilled workers.

- Increased Insurance Premiums: Insurers often increase premiums for companies with a history of safety violations.

Benefits Of Adhering To Safety Standards

While compliance might seem like a burden, it actually offers numerous benefits. It’s not just about avoiding penalties; it’s about creating a better, more productive work environment. Some key advantages include:

- Improved Worker Health and Safety: The most important benefit is protecting your workers from dust-related illnesses and injuries. A healthy workforce is a more productive workforce.

- Reduced Downtime: By preventing accidents and illnesses, you can minimise downtime and keep your project on schedule.

- Enhanced Productivity: A safe and healthy work environment boosts morale and productivity.

- Better Reputation: A strong safety record enhances your company’s reputation, making you a more attractive partner for clients and subcontractors.

- Lower Costs: In the long run, compliance can save you money by reducing the risk of fines, legal action, and insurance premium increases.

Investing in dust suppression and adhering to safety standards is not just a legal requirement; it’s a smart business decision that protects your workers, your reputation, and your bottom line.

Effective Dust Suppression Techniques

So, you’re looking for ways to keep dust down on your construction site? Good on ya! It’s not just about being a good neighbour; it’s about keeping your workers safe and complying with the law. Let’s run through some effective techniques.

Water Spraying Methods

Water is often the first line of defense, and for good reason. It’s relatively cheap and easy to apply. But it’s not just about hosing everything down; there’s a bit more to it than that. The key is to use water in a way that wets the dust particles without creating a muddy mess.

- Sprinkler Systems: Setting up sprinkler systems in areas where dust is generated can provide continuous suppression.

- Water Trucks: These are great for larger sites and roadways. They can cover a lot of ground quickly.

- Handheld Hoses: Useful for targeted areas and spot treatment. Just be mindful of water usage.

Using water effectively means considering the droplet size. Finer droplets are better for capturing dust particles, while larger droplets are better for wetting surfaces. You might need to adjust your approach depending on the type of dust and the weather conditions.

Chemical Suppressants

When water alone isn’t cutting it, chemical suppressants can be a good option. These products work by binding dust particles together, making them too heavy to become airborne. There are many types of chemical suppressants available, so it’s important to choose one that’s appropriate for your specific needs and environmental conditions.

- Lignosulfonates: These are derived from wood pulp and are effective at binding dust particles.

- Calcium Chloride: This is a salt that attracts moisture, keeping surfaces damp and dust-free.

- Polymer-Based Suppressants: These form a durable crust on the surface, preventing dust from becoming airborne.

It’s worth noting that some chemical suppressants can have environmental impacts, so it’s important to use them responsibly and in accordance with the manufacturer’s instructions. Always check the safety data sheet (SDS) before using any chemical product.

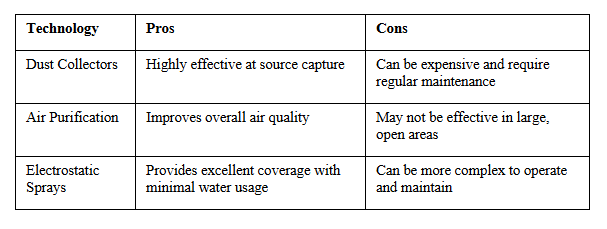

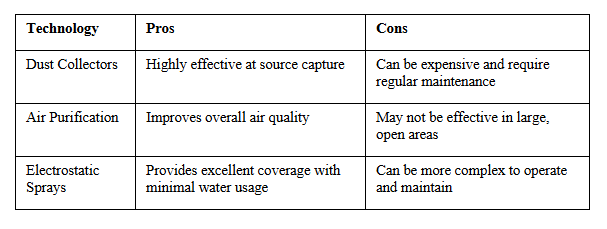

Innovative Technologies In Dust Control

Beyond water and chemicals, there are some pretty cool new technologies emerging in the world of dust control. These can be more expensive upfront, but they can also be more effective and efficient in the long run.

- Dust Collectors: These are industrial-strength vacuum cleaners that capture dust at the source.

- Air Purification Systems: These systems filter dust particles out of the air, improving air quality on site.

- Electrostatic Sprays: These sprays use an electrical charge to attract water droplets to dust particles, providing more effective coverage.

Keeping dust under control is a challenge, but with the right techniques and technologies, you can create a safer and healthier work environment for everyone.

Guarda Systems: Leading The Way In Dust Control

When it comes to keeping construction sites safe and compliant during concrete and masoney cutting and drilling, having the right dust control systems in place is a must. That’s where companies like Guarda Systems come in. They’re not just selling equipment; they’re providing solutions to a problem that affects everyone on site, and even the surrounding community. So, what makes Guarda stand out, and how can their systems make a real difference to your project?

Overview Of Guarda’s Dust Suppression Solutions

Guarda Systems offers a range of dust suppression solutions designed to tackle cutting and drilling tasks on construction sites.

Case Studies Demonstrating Effectiveness