Dust suppression on construction sites is more important than many people realise. Silica dust can pose serious health risks. In this article, we’ll explore why controlling dust during masonry cutting is essential, the regulations surrounding it, and how Guarda Systems is making a difference with their dust control solution. We’ll also look at the costs involved and best practise for keeping construction sites safe and compliant.

Key Takeaways

- Airborne dust can cause significant health risks, particularly from crystalline silica exposure.

- Compliance with silica dust regulations is crucial to avoid exposing workers and hefty fines.

- Investing in effective dust suppression can lead to long-term cost savings.

- Guarda Systems provides innovative solutions for effective dust control on construction sites.

- Regular training and monitoring are essential for maintaining dust control compliance.

Understanding The Risks Of Airborne Dust

Construction sites, while hubs of progress, unfortunately also generate a lot of dust. It’s easy to dismiss it as a minor nuisance, but airborne dust poses significant risks that need addressing. Let’s look at why dust suppression is so important.

Health Hazards Associated With Silica Dust

One of the biggest concerns is silica dust. This is created when materials like concrete, stone, and sand are cut, ground, or drilled. When inhaled, these tiny particles can cause serious and irreversible lung damage. Prolonged exposure can lead to silicosis, a debilitating lung disease, as well as an increased risk of lung cancer and other respiratory problems. It’s not just a long-term risk either; even short-term exposure can result in irreversible lung damage.

Environmental Concerns Related To Dust

It’s not just people who are affected; airborne dust also has environmental consequences. Dust clouds can travel long distances, settling on surrounding vegetation and water sources. This can disrupt local ecosystems, affecting plant growth and water quality. Dust deposition can also contaminate soil, altering its composition and potentially harming wildlife. Furthermore, the sheer volume of dust generated by construction sites contributes to air pollution, impacting air quality in surrounding areas. It’s a problem that extends beyond the site itself.

Regulatory Compliance And Its Importance

Navigating the world of construction isn’t just about hard hats and heavy machinery; it’s also about understanding and adhering to a complex web of regulations. Compliance with workplace safety standards is not merely a suggestion; it’s a legal obligation designed to protect workers, the environment, and the community. Ignoring these rules can lead to hefty fines, project delays, and, most importantly, put lives at risk. Let’s break down why regulatory compliance is so important.

Overview Of WorkSafe And OSHA Regulations

In Australia, WorkSafe is the primary body responsible for overseeing workplace health and safety. They set the standards, conduct inspections, and enforce regulations to ensure businesses provide a safe working environment. Similarly, in other countries, organisations like OSHA (Occupational Safety and Health Administration) in the United States play a comparable role. These bodies have specific guidelines regarding dust control, particularly concerning silica compliance, given the severe health risks associated with inhaling silica dust. Understanding the specific requirements of WorkSafe in your state or territory is the first step towards ensuring a safe and compliant construction site. These regulations often cover:

- Permissible exposure limits (PELs) for hazardous substances like silica.

- Requirements for air monitoring and personal protective equipment (PPE).

- Mandatory training programmes for workers on dust control measures.

Consequences Of Non-Compliance

Failing to meet regulatory requirements can have serious repercussions. The consequences extend beyond just financial penalties. Here’s what you might face:

- Fines: WorkSafe and similar bodies can issue substantial fines for breaches of safety regulations. These fines can quickly add up, especially for repeat offences.

- Project Delays: Non-compliance can lead to work stoppages while issues are addressed, causing significant delays and cost overruns.

- Legal Action: In severe cases, companies and individuals can face legal action, including prosecution for negligence.

- Reputational Damage: A poor safety record can damage your company’s reputation, making it harder to win contracts and attract skilled workers.

- Increased Insurance Premiums: Insurers often increase premiums for companies with a history of safety violations.

Benefits Of Adhering To Safety Standards

While compliance might seem like a burden, it actually offers numerous benefits. It’s not just about avoiding penalties; it’s about creating a better, more productive work environment. Some key advantages include:

- Improved Worker Health and Safety: The most important benefit is protecting your workers from dust-related illnesses and injuries. A healthy workforce is a more productive workforce.

- Reduced Downtime: By preventing accidents and illnesses, you can minimise downtime and keep your project on schedule.

- Enhanced Productivity: A safe and healthy work environment boosts morale and productivity.

- Better Reputation: A strong safety record enhances your company’s reputation, making you a more attractive partner for clients and subcontractors.

- Lower Costs: In the long run, compliance can save you money by reducing the risk of fines, legal action, and insurance premium increases.

Investing in dust suppression and adhering to safety standards is not just a legal requirement; it’s a smart business decision that protects your workers, your reputation, and your bottom line.

Effective Dust Suppression Techniques

So, you’re looking for ways to keep dust down on your construction site? Good on ya! It’s not just about being a good neighbour; it’s about keeping your workers safe and complying with the law. Let’s run through some effective techniques.

Water Spraying Methods

Water is often the first line of defense, and for good reason. It’s relatively cheap and easy to apply. But it’s not just about hosing everything down; there’s a bit more to it than that. The key is to use water in a way that wets the dust particles without creating a muddy mess.

- Sprinkler Systems: Setting up sprinkler systems in areas where dust is generated can provide continuous suppression.

- Water Trucks: These are great for larger sites and roadways. They can cover a lot of ground quickly.

- Handheld Hoses: Useful for targeted areas and spot treatment. Just be mindful of water usage.

Using water effectively means considering the droplet size. Finer droplets are better for capturing dust particles, while larger droplets are better for wetting surfaces. You might need to adjust your approach depending on the type of dust and the weather conditions.

Chemical Suppressants

When water alone isn’t cutting it, chemical suppressants can be a good option. These products work by binding dust particles together, making them too heavy to become airborne. There are many types of chemical suppressants available, so it’s important to choose one that’s appropriate for your specific needs and environmental conditions.

- Lignosulfonates: These are derived from wood pulp and are effective at binding dust particles.

- Calcium Chloride: This is a salt that attracts moisture, keeping surfaces damp and dust-free.

- Polymer-Based Suppressants: These form a durable crust on the surface, preventing dust from becoming airborne.

It’s worth noting that some chemical suppressants can have environmental impacts, so it’s important to use them responsibly and in accordance with the manufacturer’s instructions. Always check the safety data sheet (SDS) before using any chemical product.

Innovative Technologies In Dust Control

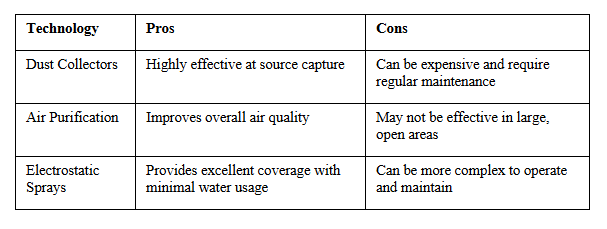

Beyond water and chemicals, there are some pretty cool new technologies emerging in the world of dust control. These can be more expensive upfront, but they can also be more effective and efficient in the long run.

- Dust Collectors: These are industrial-strength vacuum cleaners that capture dust at the source.

- Air Purification Systems: These systems filter dust particles out of the air, improving air quality on site.

- Electrostatic Sprays: These sprays use an electrical charge to attract water droplets to dust particles, providing more effective coverage.

Keeping dust under control is a challenge, but with the right techniques and technologies, you can create a safer and healthier work environment for everyone.

Guarda Systems: Leading The Way In Dust Control

When it comes to keeping construction sites safe and compliant during concrete and masoney cutting and drilling, having the right dust control systems in place is a must. That’s where companies like Guarda Systems come in. They’re not just selling equipment; they’re providing solutions to a problem that affects everyone on site, and even the surrounding community. So, what makes Guarda stand out, and how can their systems make a real difference to your project?

Overview Of Guarda’s Dust Suppression Solutions

Guarda Systems offers a range of dust suppression solutions designed to tackle cutting and drilling tasks on construction sites.

Case Studies Demonstrating Effectiveness

Talk is cheap, right? That’s why it’s important to look at real-world examples of how Guarda’s systems have performed. I’ve seen a few case studies where their solutions have significantly reduced dust levels on construction sites, leading to improved air quality and fewer health complaints from workers. One project saw a >90% reduction in airborne dust after implementing a Guarda system. It’s these kinds of results that really highlight the value of investing in effective dust control.

Partnerships With Construction Companies

Guarda Systems doesn’t just sell their products and walk away. They actively partner with construction companies to ensure their systems are properly implemented and maintained. This collaborative approach is what sets them apart. They work closely with site managers and workers to understand their specific needs and challenges, and then tailor their solutions accordingly. This might involve:

- Providing on-site training for workers on how to use the equipment properly.

- Offering regular maintenance and support to keep the systems running smoothly.

- Conducting dust monitoring to ensure the systems are performing effectively.

By building these strong partnerships, Guarda Systems is helping construction companies create safer, healthier, and more productive work environments. It’s not just about meeting regulatory requirements; it’s about looking after the well-being of the workforce and the community.

Cost Implications Of Dust Management

It’s easy to see dust control as just another expense on a construction site. But when you look closer, managing dust effectively can actually save you money in the long run. Ignoring it? That’s where the real costs start to pile up. Let’s break down the financial side of dust management.

Financial Benefits Of Investing In Dust Control

Investing in dust control upfront might seem like an added cost, but it can lead to significant savings. Think about it: cleaner air means healthier workers, and healthier workers take fewer sick days. Productivity goes up, and project timelines stay on track. Plus, there’s less wear and tear on equipment when it’s not constantly exposed to abrasive dust. Effective dust control protects your bottom line by minimising downtime and boosting efficiency.

Long-Term Savings Through Compliance

Staying compliant with regulations like those administered by WorkSafe and OSHA isn’t just about avoiding fines; it’s about protecting your business’s future. Compliance often leads to better safety practices overall, reducing the risk of accidents and injuries. This, in turn, lowers insurance premiums and workers’ compensation costs. It’s a win-win: you’re doing the right thing and saving money at the same time. Here are some reasons to control dust on job sites:

- Reduced healthcare costs for workers.

- Lower insurance premiums due to fewer accidents.

- Increased productivity from a healthier workforce and reduced cleanup time and costs..

Cost Of Potential Fines And Legal Issues

Ignoring dust control can lead to hefty fines and legal battles. WorkSafe and OSHA take dust-related violations seriously, and the penalties can be substantial. But the costs don’t stop there. If workers develop long-term health problems from dust exposure, you could face lawsuits and compensation claims that could seriously impact your business’s financial stability. It’s far cheaper to invest in dust suppression than to deal with the consequences of non-compliance.

Failing to manage dust isn’t just a safety issue; it’s a financial risk. The potential costs of fines, legal action, and decreased productivity far outweigh the investment in effective dust control measures.

Best Practices For Implementing Dust Suppression

Okay, so you’re ready to get serious about dust suppression on your construction site. That’s great! But just buying the equipment isn’t enough. You need a plan and some solid practices to make sure it actually works. Here’s what I’ve learned about getting it right.

Training Workers On Dust Control Measures

First up, your team needs to know what’s going on. It’s not enough to show them how to use the equipment once. They need to understand why dust control is important and how to use the equipment properly.

- Run regular training sessions: Don’t just do it once. Keep the training going so everyone stays up to date.

- Cover the health risks: Make sure they know about silicosis and other dust-related illnesses. It’ll make them take it seriously.

- Show them how to use the equipment: Whatever you’re using, make sure they know how to operate it safely and effectively.

Regular Maintenance Of Suppression Equipment

Dust suppression gear isn’t going to work if it’s broken. Regular maintenance is key to keeping everything running smoothly. Think of it like your car – you wouldn’t skip services, would you?

- Create a maintenance schedule: Set up a regular schedule for checking and servicing all your dust control equipment.

- Keep spare parts on hand: Nothing worse than having a crucial piece of equipment break down and having to wait weeks for a replacement.

- Train someone on-site to do basic repairs: A little bit of training can go a long way in keeping things running.

Monitoring Dust Levels On Site

How do you know if your dust suppression efforts are actually working? You need to monitor dust levels. This will help you adjust your approach and make sure you’re meeting regulations.

- Use dust monitors: Invest in some reliable dust monitoring equipment to get accurate readings.

- Take regular measurements: Don’t just do it once in a while. Take measurements regularly to track changes over time.

- Adjust your strategy as needed: If dust levels are too high, tweak your suppression methods until you get them under control.

Implementing these best practices isn’t just about ticking boxes; it’s about creating a safer, healthier, and more productive work environment for everyone on site. Plus, you’ll avoid those hefty fines from WorkSafe. It’s a win-win!

The Future Of Dust Suppression In Construction

The construction industry is always changing, and dust suppression construction is no exception. As we look ahead, several exciting developments promise to make our jobsites safer and more sustainable. It’s not just about meeting today’s standards; it’s about preparing for tomorrow’s challenges.

Emerging Technologies And Innovations

We’re seeing some cool new tech enter the jobsite dust safety space. Think advanced sensor technology that can monitor dust levels in real-time, providing immediate feedback and allowing for quicker responses. There’s also increased interest in using drones for targeted dust suppression in hard-to-reach areas. These drones can be equipped with spray systems to apply water or suppressants precisely where needed, reducing waste and improving efficiency.

Here’s a quick look at some emerging technologies:

- Real-time monitoring systems: Sensors that provide instant data on dust particle concentration.

- Drone-based suppression: Drones equipped with spraying capabilities for targeted application.

- AI-powered systems: Using artificial intelligence to predict and manage dust generation based on weather patterns and site activities.

Sustainability In Dust Management

Sustainability is becoming a major focus. People are looking for eco-friendly dust suppression equipment for construction options that minimise environmental impact. This includes using biodegradable suppressants, recycled water, and energy-efficient equipment. The goal is to reduce our carbon footprint while still maintaining effective dust control.

Sustainable dust management isn’t just a trend; it’s a necessity. By adopting greener practices, we can protect the environment and create healthier work environments for everyone.

The Role Of Automation In Dust Control

Automation is set to play a big role in the future. Imagine fully automated dust suppression systems that adjust their output based on real-time conditions, without needing constant human intervention. This not only improves efficiency but also reduces the risk of human error. Automated systems can also collect data and generate reports, helping us to better understand and manage dust levels over time. This will lead to safer and more productive construction sites.

Here are some benefits of automation:

- Increased efficiency and reduced labour costs.

- Improved accuracy and consistency in dust suppression.

- Better data collection and reporting for compliance purposes.

As we look ahead, dust suppression in construction is becoming more important than ever. New technologies are being developed to keep workers safe and reduce dust in the air. It’s time to take action! Visit our website to learn more about how we can help you with effective dust control solutions during concrete and masonry cutting. Don’t wait until it’s too late!

Wrapping It Up

In summary, dust suppression on construction sites is not just a nice-to-have; it’s a must. The risks from airborne silica and other fine particles can lead to serious health issues for workers, and ignoring these dangers can result in hefty fines from WorkSafe or OSHA. By implementing effective dust control measures, like those offered by Guarda Systems, you can create a safer work environment and keep your team protected. It’s about being responsible and compliant, ensuring everyone goes home safe at the end of the day. For more information on dust suppression products and safety resources, check out our product page.

Frequently Asked Questions

What are the dangers of dust on construction sites?

Dust from construction can be harmful to health, especially silica dust. It can cause silicosis and other serious health issues.

What rules do we need to follow about dust control?

There are laws from WorkSafe and OSHA that require construction sites to manage dust. Following these rules helps keep workers safe and avoids fines.

What are some ways to reduce dust on sites?

Common methods include using water to wet down areas, applying special dust control chemicals, and using new technologies designed to trap dust.

Why should companies invest in dust control?

Investing in dust control can save money in the long run. It helps avoid fines and keeps workers healthy, which can reduce costs related to accidents.

How can we make sure dust control measures are effective?

Training workers on how to control dust, regularly checking equipment, and monitoring dust levels are key practices to ensure dust control is working.